Flocking

During my research stage, I came across "Flocking", a substance I have used before in silicone to pigment it. I have never used it however, to apply directly onto a prosthetic piece to make it appear as textured skin. I thought it would be a great way for me to gain a bit of knowledge into the material, and to also experiement using it.

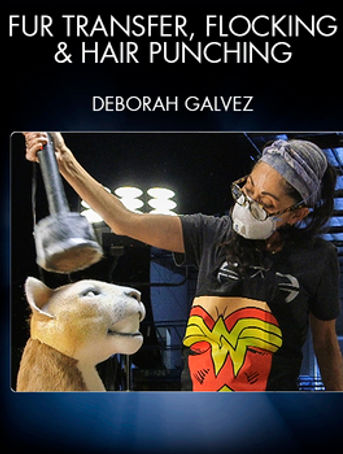

Fur transfer, Flocking & Hair punching - Stan Winston Studios DVD

It was so inspiration to watch a DVD demonstrating how to use a flocking machine, and better still being educated in the process.

I thoroughly enjoyed observing the techniques and methods used to create the animatronic skin.

This was something I would interesting in pursuing after University, and it made me want to apart of actually making the animal .

I recommend this DVD for anyone who wants to create a prosthetic to look like this.

"Flocking" is a decoration process that enhances the way a wide variety of products are experienced by making ordinary surfaces seem far more magical and special. "Flocking" is the process of depositing millions of little individual cut fiber particles (called "flock") onto the surface of an article for the purpose of increasing the tactile sensation, aesthetics, color and appearance.

What is Flocking?

Uses of Flocking

Flocking is used in many ways. One example is in modeling where a grassy texture may be applied to a surface to make it look more realistic. Another is on a Christmas Trees, which may be flocked with a fluffy white spray to simulate snow. The fuzzy inside of a jewelry box is flocking, it protect fine jewelry from scratches and dings.

Applying Flocking

Flocking is defined as the application of fine particles to adhesive coated surfaces. Nowadays, this is usually done by the application of a high-voltage electric field. In a flocking machine the "flock" is given a negative charge whilst the substrate is earthed. Flock material flies vertically onto the substrate attaching to previously applied glue. A number of different substrates can be flocked including; textiles, fabric, woven fabric, paper, PVC, sponge, toys, automotive plastic.

The majority of flocking done worldwide uses finely cut natural or synthetic fibers. A flocked finish imparts a decorative and/or functional characteristic to the surface. The variety of materials that are applied to numerous surfaces through different flocking methods create a wide range of end products. The flocking process is used on items ranging from retail consumer goods to products with high technology military applications.

This is my own bought flocking that I managed to purchase online after a few hours of searching. I was given a few websites to browse through from other prosthetic artists through social media. I found this to be extremely helpful as I hadn't a clue where to even begin looking. There were a few places in London that were a flocking company, but instead of allowing you to purchase the flocking, you sent them the item you wanted to be flocked, and they'd send it back when it was complete, which isn't what I wanted. After researching a bit more into it, I realised it is called different names within the industry, I was searching flocking for prosthetics and flocking material, when in actual fact it was under " Flocking Fibres" , which again was confusing, as flocking is used for cars these days, and I wasn't sure whether they sold the correct fibres. All the prosthetic stores like Mouldlife and PS Composites didn't sell the colours I wanted, so I managed to find a link from FLOC-KING, which is also the name on eBAY, I found some great colours they were selling ( as shown above) , and also other variety of colours.

Experimenting with this material will benefit further skills I may have in the future, it will also show my exploration of materials within my project. It is always a good way to demonstrate using new materials, even if it means you don't like it, or it didn't go very well, At least I can say I tried.